Soluciones

La gama de negocios de construcción de caballos se extiende a todo el mundo y sirve a miles de clientes con productos, orientación técnica especializada en construcción, y somos testigos del reinicio de la marca china con ellos.

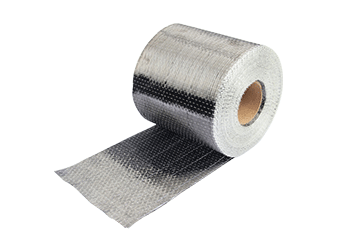

Fibra De Carbono

Cotización

El mundo de hoy no es pacífico, se han producido todo tipo de accidentes o explosiones deliberadas en todo el mundo, y los ataques aéreos a gran escala han causado enormes daños a edificios y enormes pérdidas de vidas y bienes humanos, al tiempo que atacan con precisión objetivos terrestres. Por lo general, la capacidad de los edificios civiles para resistir las cargas explosivas es muy pequeña. El colapso de edificios y las salpicaduras de alta velocidad de fragmentos estructurales causadas por la capacidad insuficiente de resistencia a la explosión de la estructura amenazan seriamente la seguridad del personal Interior. Cómo mejorar la capacidad a prueba de explosiones de los edificios existentes y garantizar la seguridad de la vida y los bienes de las personas ha atraído una gran atención de la comunidad de ingeniería civil en todo el mundo.

En la actualidad, la mayoría de los edificios son estructuras de hormigón armado, y es urgente un método de refuerzo económico, eficiente y conveniente a prueba de explosiones. Con el desarrollo de nuevas tecnologías de materiales, se han desarrollado diversos materiales de fibra reforzada de alta tecnología, como fibra de vidrio (gf), fibra de carbono (cf), fibra aramida (af), etc. de todas las fibras reforzadas, CF es actualmente la más compleja y utilizada en el campo de la ingeniería civil.

El polímero reforzado con fibra de carbono (cfrp) tiene excelentes propiedades mecánicas. Debido a su alta resistencia, peso ligero, chapa extremadamente delgada, amplia adaptabilidad y construcción conveniente, muestra excelentes beneficios técnicos y económicos y tiene amplias perspectivas de desarrollo. La fibra de carbono tiene características incomparables de materiales como resistencia a la fatiga, resistencia a la corrosión, resistencia a la fluencia, tamaño estable de los materiales y construcción conveniente, y no solo es un material de alta tecnología insustituible en los campos aeroespacial, aeroespacial y militar. Con la madurez, popularización y mejora sustancial de la relación calidad - precio de la tecnología, se ha utilizado ampliamente en la industria, la construcción y otros campos civiles.

1 características de la tecnología de refuerzo de tela de fibra de carbono unida

El refuerzo de polímeros reforzados con fibra de carbono (cfrp) se ha utilizado ampliamente en ingeniería civil en los últimos años. En este método, los tejidos de fibra de carbono dispuestos en la misma dirección se impregnan con resina epoxi y se adhieren a la superficie de la estructura a temperatura ambiente. Como nuevo todo, los dos tejidos se cargan juntos. Este es un método de refuerzo muy simple y eficaz. El método de refuerzo tiene las siguientes características:

1.1 alta intensidad y alta eficiencia. La resistencia a la tracción del CFRP es aproximadamente 10 veces mayor que la del acero, y el módulo de elasticidad es igual al del acero (aproximadamente 0,01); La resistencia específica (es decir, la relación entre la resistencia y la densidad del material) puede alcanzar más de 2000mpa / (g.cm - 3), mientras que la resistencia específica del acero A3 es de solo unos 59mpa / (g.cm - 3), y su módulo específico también es superior al del acero.

1.2 peso ligero y espesor delgado. La tecnología más madura también es la más consumida. El grado es de aproximadamente 0,1 - 0,2 mm, y la densidad de área es de aproximadamente 1 / 100 de la placa de acero; Después del refuerzo del cfrp, la masa y el tamaño de la estructura original no aumentarán y el espacio de uso no disminuirá.

1.3 tiene buena durabilidad y resistencia a la corrosión. La tela de fibra de carbono se puede usar a 2000 ℃ y no se derrite ni se ablanda en un ambiente no oxidativo a 3000 ℃. El material de tela de fibra de carbono tiene una buena resistencia a la corrosión en diversas condiciones ambientales y puede resistir la corrosión de ácidos, álcalis, sales y entornos atmosféricos que a menudo se encuentran en edificios. Tiene una mejor resistencia a la fatiga. Por lo tanto, todo tipo de obras se pueden reforzar con cfrp.

1.4 La construcción es conveniente. La tela de fibra de carbono es suave, fácil de procesar, manual, sin maquinaria grande, sin operación húmeda, y la eficiencia de la construcción es alta. Si se elige el adhesivo adecuado, se puede lograr un refuerzo rápido.

1.5 amplia gama de aplicaciones. No está limitado por la forma estructural, El CFRP se puede pegar en la zona de tensión, lo que puede mejorar la capacidad de carga de los componentes curvados y complementar las deficiencias de las barras de acero. Pegar a ambos lados de la viga puede mejorar la capacidad de resistencia al Corte de la viga. Enredarse en el exterior de la columna de hormigón puede inhibir la deformación lateral del hormigón, mejorando así la capacidad de carga y la relación de compresión axial de la columna. Los nodos alrededor de trass pueden fortalecer los nodos.

Adecuado para vigas, placas, columnas, puentes, túneles, chimeneas y otras estructuras de varios edificios industriales y civiles. No cambia la forma de la estructura ni afecta su apariencia.

1.6 La calidad de la construcción es fácil de garantizar. La artesanía perfecta y los trabajadores capacitados pueden lograr más del 99% del área de pegado efectiva y los costos de mantenimiento son Bajos.

2 investigación sobre la resistencia a la explosión de estructuras de hormigón armado reforzadas con fibra de carbono en el extranjero

Khalid M. mosalam es un ejemplo de CFRP y cfrp, así como de computadoras y computadoras, así como de CFRP y computadoras y computadoras y cfrp, y CFRP es el ejemplo en este caso.

(1) la capacidad de carga de la placa de hormigón armado reforzada por CFRP se ha duplicado.

(2) bajo la acción de la carga de explosión, la rigidez general y la resistencia de las placas bidireccionales de hormigón armado reforzadas por CFRP han aumentado considerablemente. Debido a la destrucción del hormigón, la frecuencia de base de las placas no reforzadas se redujo en un 85%, y después del refuerzo se redujo en menos del 50%. Además, el desplazamiento máximo de las placas de refuerzo CFRP antes del refuerzo se redujo entre un 40% y un 70%.

(3) bajo carga explosiva, el refuerzo de fibra de carbono de la placa de hormigón armado limita la expansión temporal y Espacial de los haces de acero de rendimiento y mejora significativamente su capacidad para resistir daños locales.

(4) el refuerzo de doble cara es el mejor.

3. Resumen

Las ventajas de la tecnología de refuerzo de fibra de carbono son obvias. Muchas instituciones de investigación científica en el país y en el extranjero han llevado a cabo una gran cantidad de trabajo de investigación, la mayoría de los cuales se aplican a proyectos prácticos, que se registran en muchas literaturas. Sin embargo, la mayoría de las investigaciones sobre la tecnología de refuerzo de fibra de carbono se limitan a la carga estática, y no hay informes de investigación sobre componentes de hormigón armado reforzados con fibra de carbono bajo carga explosiva en china.

Una serie de estudios experimentales extranjeros han demostrado que la fibra de carbono puede mejorar efectivamente la resistencia a la explosión de la estructura, y su capacidad general de carga y resistencia a daños locales se han mejorado significativamente. Sin embargo, la resistencia al cizallamiento del CFRP es muy baja, la tasa de extensión es muy pequeña, menos de 1 / 10 del acero general, la curva de relación esfuerzo - tensión es casi lineal, sin plataforma plástica, en este sentido, El CFRP es un material frágil que debe tenerse en cuenta en el diseño y construcción. las propiedades dinámicas del propio material cf, los factores que afectan el efecto del refuerzo del CFRP en la construcción existente bajo carga explosiva, métodos de diseño, técnicas de construcción y otros problemas deben estudiarse más a fondo.

Puede encontrar cualquier cosa que necesite, confíe en probar estos productos y encontrará la gran diferencia después de eso.

Tejido de fibra de carbono unidireccional de alta resistencia para refuerzo de compuesto de polímero reforzado con fibra (FRP).

Impregnación y pasta de componentes reforzados de superficie y productos de fibra.

Lámina de fibra de carbono pultruída para reforzamiento de estructuras