Soluciones

La gama de negocios de construcción de caballos se extiende a todo el mundo y sirve a miles de clientes con productos, orientación técnica especializada en construcción, y somos testigos del reinicio de la marca china con ellos.

There are many researches on the normal section, oblique section bearing capacity, bearing capacity and ductility of the flexural members strengthened by CFRP, and the design and calculation methods can be more mature. However, the above calculation methods are based on the CFRP cloth and concrete bond firmly, CFRP cloth strain reached the allowable strain before peeling failure.

There are many researches on the normal section, oblique section bearing capacity, bearing capacity and ductility of the flexural members strengthened by CFRP, and the design and calculation methods can be more mature. However, the above calculation methods are based on the CFRP cloth and concrete bond firmly, CFRP cloth strain reached the allowable strain before peeling failure. But experiments show that. The effect of CFRP cloth on strengthening concrete structure is closely related to the bond performance between CFRP and concrete, and the stripping failure of CFRP cloth is a common form of failure, which is very sudden, brittle, and the use of CFRP cloth is also poor.

1 carbon fiber(CFRP) reinforced concrete beams peel failure mode

1.1 classification according to the location of peeling destruction.

According to the location of peeling failure, it can be divided into the end stripping failure and the middle peeling failure.

1.1.1 end peeling failure

This peeling damage begins at the ends and develops across the middle. The failure is caused by the stress concentration at the end, and is related to the loading mode, the bonding length of carbon fiber sheet and other factors. If two points are loaded centrally and the shear span is small, shear cracks will easily appear near the bearing, and stress concentration will be formed near the interface between CFRP and concrete. In addition, when the bond length of CFRP is small and there is no reliable additional anchorage, the end peeling failure will generally occur.

1.1.2 central peel failure

This peeling destruction begins in the middle and extends to the end. This kind of failure is caused by the stress concentration in the middle of the span. For example, the bending moment and shear force in the middle of the span are the largest, and the cracks will appear near the middle of the span first. At this time, the stress concentration is formed at the interface between CFRP and concrete near the middle of the span. If the effective bond extension is long enough, the middle peel failure will occur.

1.2 classification according to peeling failure mechanism

1.2.1 concrete protective layer is pulled down.

Such destruction usually occurs at the ends. If the shear span is small, the strength of concrete is low, and the shear capacity is insufficient.

1.2.2 CFRP spalling along the concrete surface of the beam bottom

If the concrete is slightly higher, the shear strength is stronger. Generally, this kind of damage will occur. The damage starts from the end and extends to the middle of the span.

1.2.3 causes longitudinal spalling of CFRP along beams due to bending shear cracks or bending cracks.

If the shear span of the beam is large and the bond elongation of CFRP is long enough or it is possible to attach anchorage, the peeling failure usually begins with the shear span crack. And to the end of the development; or the beam has enough shear capacity, and the bending capacity is not enough. When the bond elongation length of FRP is long enough or the additional anchorage is reliable, the peeling failure usually starts from the bending crack in the middle of the span and extends to the end of one side. For the concentrated load in the middle of the span, this kind of failure will generally occur.

3 factors affecting peel failure

The peeling failure between fiber sheet and concrete is a failure phenomenon with uncertainty and influenced by many factors. It is mainly related to the strength of concrete, the thickness of protective layer, the number of CFRP bonding layers, the anchorage form of CFRP, the loading form of the added member, the loading history, the construction quality and so on.

3.1 concrete strength

Concrete strength is the most important factor affecting the bond performance between fiber sheet and concrete. The test results show that the bond strength between concrete and composite materials increases with the increase of concrete strength within a certain range of concrete strength. The lower the strength of concrete is, the easier it is to peel off. Even if the strength of the concrete is higher, it may be because the formwork effect of the shallow concrete can not reach the test strength value; or for the existing concrete members, because of aging, steel corrosion and other reasons, there are longitudinal and transverse micro-cracks in the surface of the shallow part of the concrete, low strength, peeling.

3.2 anchoring length is the same as anchor.

Anchorage length and anchorage mode are also important factors affecting the interfacial bond between fiber sheet and concrete. The shorter the anchorage length, the greater the local bond stress, the more serious the stress concentration at the end, and the greater the possibility of the end peeling failure. When the anchor is longer than a certain length, the bond stress basically does not increase. The possibility of end peeling failure is greatly reduced. In the middle of the way, there was a central peel failure. In addition, the test shows that the additional anchor has great influence on the peeling resistance of the same beam. For example, the additional anchorage at the end can reduce the possibility of the end peeling. Generally speaking, the reinforcement members can not achieve Self-anchorage by extending the bonding length of CFRP, which requires a variety of additional anchorage perimeter measures to achieve. The effect of anchoring with U-shaped hoop (carbon fiber cloth U-shaped hoop, steel plate U-shaped hoop) to prevent longitudinal carbon fiber cloth peeling is obvious.

3.3 reinforcement material and reinforcement amount

For reinforced concrete beams strengthened with fiber sheets, the increase of ultimate bearing capacity mainly depends on the transfer of bonding stress by bonding layer, and the resin stiffness is large. Good flexibility of the fiber sheet can effectively reduce the peeling stress, thus reducing the possibility of peeling failure; the greater the amount of reinforcement, the greater the thickness and stiffness of carbon fiber sheet, coupled with the increase in the amount of reinforcement.

3.4 construction quality

The bonding of CFRP sheet is smooth and of good quality, which can ensure the uniform force of CFRP sheet in transverse direction and reduce the peeling damage caused by local separation. The resin glue between CFRP sheet and concrete and between CFRP sheet and CFRP sheet is full and uniform, which is beneficial to prevent the occurrence and development of peeling damage.

3.5 load history

The experimental results show that the possibility of peeling failure is similar to that of strengthening without a single stress, but with the development of cracks, the possibility of peeling failure is similar. The possibility of peeling and breaking will increase if reinforcement is not taken when necessary.

3.6 loading form

The stripping failure of shear-bending section towel near the inclined crack of loading point often occurs under concentrated load, and it is accompanied by stripping failure of mid-span pure bending section.

Puede encontrar cualquier cosa que necesite, confíe en probar estos productos y encontrará la gran diferencia después de eso.

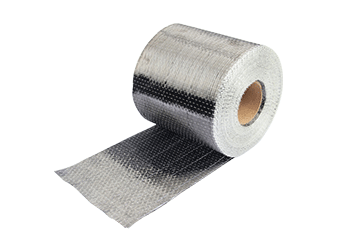

Tejido de fibra de carbono unidireccional de alta resistencia para refuerzo de compuesto de polímero reforzado con fibra (FRP).

Impregnación y pasta de componentes reforzados de superficie y productos de fibra.

Lámina de fibra de carbono pultruída para reforzamiento de estructuras