Soluciones

La gama de negocios de construcción de caballos se extiende a todo el mundo y sirve a miles de clientes con productos, orientación técnica especializada en construcción, y somos testigos del reinicio de la marca china con ellos.

FRP composite strengthening of the bridge is similar to that of bonding the iron plate to the bearing edge of the cement component by chemical bonding agent, so that it can bear the supporting and compressive functions together with the bridge components, and then enhance the deformation resistance and bearing capacity of the bridge structure.

Aiming at all kinds of highway and water conservancy bridge projects which are in service and play the traffic function effectively in our country, it is an urgent task for the competent authorities of various trades in the traffic field to implement the comprehensive and complete reinforcement and maintenance process of bridge structure. At present, many bridge reinforcement techniques widely used have some common defects which are harmful to the strength of the bridge frame. The new advanced CFRP composite strengthening technology can effectively compensate for the fatal defects, and the construction is convenient, which can greatly improve the deformation resistance of the bridge frame.

Most of the bridges designed and constructed in our country in the 1960s and 1970s have low load index. At present, these bridges are still in service, and the traffic scale and cyclic load are increasing continuously. Especially after the promotion of trailer and container transport mode, the vast majority of bridges nowadays have fully exposed that they can not meet the current highway transport on the bridge quality and performance requirements of a higher level. Therefore, strengthening the investigation and evaluation of the damaged condition of the existing service bridges and using appropriate solidification and maintenance technology to reinforce the treatment will greatly promote the healthy development of China's current highway transportation.

At present, the solidification process for bridge structure includes: expanding the cross-section area of cement bridge; iron plate assisted solidification process; adding prestressing technology outside the bridge structure; innovating the solidification process of bridge frame system. This article focuses on FRP composite reinforcement technology.

1.1 expand the bridge section reinforcement technology

This technology basically relies on expanding the bearing area, increasing the load level of the bridge, and enlarging the coverage of the bridge reinforcement application. Two measures can be taken to expand the cross-sectional area of cement: one is to increase the thickness of deck slab, that is, to deepen the size of the reinforcing layer of the deck, so as to increase the bearing thickness of the main girder and the rigidity of the bearing section, and to strengthen the integrity of the bridge as a whole. The second is to increase the three-dimensional dimensions of the main girder and beam reinforcement load frame, increase the thickness of the main girder size and restrain bending deformation.

Because the newly poured cement in the process of bridge construction belongs to the follow-up secondary stress structure, the stress structure at the junction is complicated. In addition, it takes a long time to implement the solidification process, which seriously interferes with the operation of vehicles on the bridge deck, and it is very difficult to pour at the bottom and side of the beam. The reinforcement technology of this bridge is mainly applied to cross-beam bridge and arch bridge with small size and limited construction space.

1.2 bridges are externally prestressed.

The reinforcement technology of the bridge structure is that the deck beam is used as the base of fixed anchor, and the prestressing force given by the stressed steel bars in the tensile bearing zone is used to counteract the gravity of a certain proportion, thereby reducing the load and improving the load function of the bridge structure. Its unique feature is that it can not increase the weight of the bridge itself, increase the deformation resistance of the bridge frame and restrain the function of cracks, and can achieve the goal of not affecting the free passage of vehicles on the bridge deck during the reinforcement process. However, the external prestressing of the bridge can cause considerable damage to the original bridge frame. Moreover, it is easy to occur the phenomenon that the tensioned steel bars relax again during the tensioning operation, which leads to the failure of the reinforcement process. The bridge reinforcement technology can be widely used in the bridge type which needs to carry out the long-span load function lifting process for the original bridge frame.

1.3 FRP scomposite trengthening technology

The reinforcement technology of the bridge is similar to that of bonding the iron plate to the bearing edge of the cement component by chemical bonding agent, so that it can bear the supporting and compressive functions together with the bridge components, and then enhance the deformation resistance and bearing capacity of the bridge structure.

Two groups of chemical resin bonding agents are used to bond the iron plate to the surface of the cement body with other accessory iron parts, so that the cement, chemical binder and iron plate can bear the stress load together, thereby enhancing the deformation resistance and load function of the bridge structure. To a certain extent, the steel plate can replace the bearing function of the reinforcing bar, thereby improving the supporting ability of the bridge frame. Historically, the use of this bridge structure reinforcement technology originated in the late 60s of last century. With the continuous expansion of the application scope of this technology in engineering practice, its application function shortboard is also revealed. The key point is: the use of bonded steel plates for reinforcement makes the weight of the bridge increase greatly, and the steel plates used are easy to be exposed to humid air for a long time and cause deep rust erosion, and the reinforcement effect is not prominent in the initial stage.

Carbon fiber, also known as reinforced composites, is a kind of fiber composite material. At present, the carbon fiber used in engineering is a continuous fiber which is made of multiple strands of continuous fiber bonded with the substrate through "extrusion" and "drawing" molding. The carbon fiber material can be pasted on the roof and the bottom plate of the concrete beam, so as to improve the rigidity of the beam. It can also be pasted on the web of concrete beams to improve the shear strength of beams. Carbon fiber material can not only be used for the reinforcement of the bridge superstructure, but also for the reinforcement of the bridge substructure - pier abutment, that is, winding fibers outside the pier, so that the strength and stress state of the pier can be significantly improved, so as to improve the bearing capacity of the pier. In addition, CFRP strands can also be used as prestressed tendons in prestressed concrete structures.

Usually, depending on the number of supporting frames and piers in the lower part of the simply supported beam, the continuous treatment is carried out between the simple beams so as to form a continuous bridge mode. Under the bridge deck, reinforce the steel reinforced beam or change the connection form into a fixed connection form. The application of this reinforcement technology is very successful, but careful calculation and analysis are needed before the consolidation operation is carried out.

Before construction, the characteristics of the bridge or its components should be fully investigated and studied, and the materials used, matching resins and machines should be prepared. At the same time, according to the design drawings, the construction lofting is used to determine the sticking position of the carbon fiber fabric.

The surface of the bonded concrete is ground and repaired and dried sufficiently. If wet environment, the surface should be dry.

Based on the problems of aging, breakage and crack existing in the bridge, it is necessary to innovate and adopt new technology and technology to make the strengthening process more rapid, economical and safe on the basis of widely using FRP compoaite material to strengthen the bridge.

Puede encontrar cualquier cosa que necesite, confíe en probar estos productos y encontrará la gran diferencia después de eso.

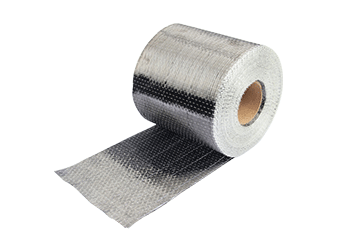

Tejido de fibra de carbono unidireccional de alta resistencia para refuerzo de compuesto de polímero reforzado con fibra (FRP).

Lámina de fibra de carbono pultruída para reforzamiento de estructuras

Placa / laminado / banda de polímero pretensado reforzado con fibra de carbono (CFRP) para la losa, refuerzo del haz