Soluciones

La gama de negocios de construcción de caballos se extiende a todo el mundo y sirve a miles de clientes con productos, orientación técnica especializada en construcción, y somos testigos del reinicio de la marca china con ellos.

Carbon fiber fabric have the advantages of stable structure, light weight, good cold resistance, corrosion resistance and heat resistance, and are widely used in pure tensile components. This is extremely relevant to its excellent strength and stiffness.

At present, China has developed more mature bridge engineering, and the traffic volume on the road has been increasing, while the vehicle load and traffic density are also increasing, so the load requirements for the bridge are very high. Because the vehicle's load tonnage is also rising, which will lead to insufficient bearing capacity of the bridge, there will be many problems, such as: steel corrosion, wind-blown bars, concrete cracking and so on. Some bridges simply can not reach the design life, serious degradation phenomenon is obvious, and even can not meet the use of functions. Therefore, through the transformation of technical measures and appropriate reinforcement can improve and restore the bridge traffic and bearing capacity. Therefore, the most important bridge maintenance work at present is to prolong the service life of the bridge. However, China started relatively late in this respect, but the development is relatively fast, there are many successful cases of strengthening bridges. For example: reinforcement repair of Lugou new bridge; Nanjing airport viaduct hollow slab reinforcement repair.

About carbon fiber fabric for bridge reinforced

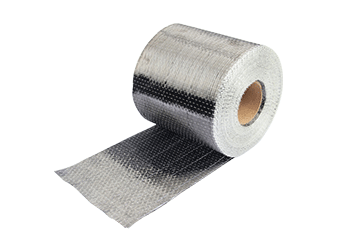

The so-called carbon fiber fabric, refers to the carbon fiber reinforced plastic, which is a kind of resin material and carbon fiber material processing, composite. Carbon fiber fabric, consisting of one-way arrangement, bundle structure, epoxy resin impregnated, reinforced fiberboard or untreated carbon fiber cloth.

Carbon fiber fabric have the advantages of stable structure, light weight, good cold resistance, corrosion resistance and heat resistance, and are widely used in pure tensile components. This is extremely relevant to its excellent strength and stiffness. It is worth noting that the tensile strength of CFRP fabric must be greater than 3000MPa in common projects, otherwise it can not be used and will have unimaginable consequences. But at the same time, we need to pay attention to these points.

1.1 The flexural capacity, or bearing capacity, of CFRP frame should not exceed 40% of its flexural capacity.

1.2 Carbon fiber fabric has tensile strain, but it is unreasonable to exceed two-thirds of its ultimate tensile strain and a smaller value in 0.01.

1.3 The tensile strength of the steel bar has a standard value, below this standard value, the use of reinforced materials is safe.

Guarantee for overall quality of FRP strengthening

1.1 Dense and smooth is essential for concrete engineering. In the construction process, do not jerry-built things happen, must pay attention to the design of mortar proportion, strictly in accordance with the design standards.

1.2 In different cases, the integrity of carbon fiber fabric should be ensured as far as possible, if the inevitable situation, have to cut off the carbon fiber fabric, should be the most appropriate treatment. It is best to stick to the planned path and avoid obstacles on the reinforcement material. When the carbon fiber cloth is lapped, the length must be greater than 100mm, and it needs to lap along the direction of the upper fiber bundle.

1.3 Therefore, in order to obtain better penetration effect, the amount of prepreg resin must be carefully and strictly controlled to reduce the amount. But at present, the amount of prepreg resin in our country is subdivided and controlled, which is quite different from foreign materials, resulting in some differences in bonding effect.

1.4 In the construction process, every step of the completion (from the base bonding to the late carbon fiber paste), should be strictly inspected, and after the completion of the acceptance of each link to record the status of completion, if there are quality problems, timely rework. Try to avoid the occurrence of sticking hollow drum, adhesion and disengagement, if the adhesive area can not reach 90% of the construction area, then sticking is failure, later will produce shedding and other conditions, solid need to rework. If a small part of the sticking is not tight, it can be remedied by filling glue injection through the needle tube. It is necessary to have the inspection and certification materials of the manufacturer.

Puede encontrar cualquier cosa que necesite, confíe en probar estos productos y encontrará la gran diferencia después de eso.

Tejido de fibra de carbono unidireccional de alta resistencia para refuerzo de compuesto de polímero reforzado con fibra (FRP).

Lámina de fibra de carbono pultruída para reforzamiento de estructuras

Placa / laminado / banda de polímero pretensado reforzado con fibra de carbono (CFRP) para la losa, refuerzo del haz