Soluciones

La gama de negocios de construcción de caballos se extiende a todo el mundo y sirve a miles de clientes con productos, orientación técnica especializada en construcción, y somos testigos del reinicio de la marca china con ellos.

Strengthening of load-bearing members on the upper part of bridge

Oblique cracks of T beams

Cause analysis: the diagonal cracks are subjected to longitudinal forces and shear stresses, and the amplitude is gradually increased from the sides to the middle. Because of the function of the diaphragm, the amplitude reaches the maximum in the middle of the intertransversal plate in the span, so the crack is produced first, and the crack will extend quickly with the passage of time, the size widens from the narrow to the inner surface. Cracks also occur in other parts of beams.

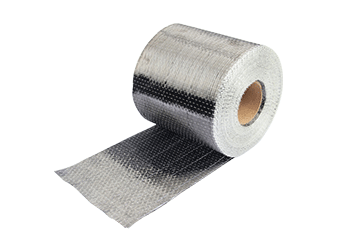

Disposal suggestion: two methods are mainly adopted: surface repair method, grouting and caulking method. The surface repair method is used for the crack width. The usual treatment is to apply cement slurry, epoxy cement or paint, asphalt and other anticorrosive materials on the surface of cracks. In order to prevent the concrete from continuing to crack under the influence of various actions, it is usually possible to stick fiberglass cloth on the surface of cracks and other measures. Grouting or caulking and sealing are adopted for wider cracks or development trend.

Longitudinal cracks in the horseshoe and the bottom of the beam of the T beam

Cause of protective layer

Cause analysis: the longitudinal cracks in the beam are mainly due to the lack of concrete protection layer, the thickness of the concrete protection layer is not enough, the concrete wrapping force is insufficient, resulting in the corrosion and expansion of the main reinforcement in the outer layer, resulting in the longitudinal cracks. Because of the large degree of roughness of concrete and the reaction with the chemical substances in wet air, the cracks cause further corrosion, and the cracks are easy to extend to the depth of the beam.

Disposal suggestion: the surface of crack is wider and the surface repair method is adopted. The usual treatment is to apply cement slurry, epoxy cement or paint, asphalt and other anticorrosive materials on the surface of cracks. In order to prevent the concrete from continuing to crack under the influence of various actions, it is usually possible to stick fiberglass cloth on the surface of cracks and other measures. Grouting or caulking and sealing are adopted for wider cracks or development trend.

Cause of force

Cause analysis: beam slab is a load-bearing member bearing dead load and dynamic load. For a long time, the vehicle dynamic load passes through the bridge deck to the beam. The construction strength of the beam is not up to the design strength. When the load accumulates more than the fatigue times it can bear, the load-bearing components will begin to produce small cracks from the bottom, and gradually extend to the inside of the beams because of the shear stress produced by the dynamic load.

Disposal suggestion: two methods are mainly adopted: surface repair method, grouting and caulking method. The surface repair method is used for the crack width. The usual treatment is to apply cement slurry, epoxy cement or paint, asphalt and other anticorrosive materials on the surface of cracks. In order to prevent the concrete from continuing to crack under the influence of various actions, it is usually possible to stick fiberglass cloth on the surface of cracks and other measures. Grouting or caulking and sealing are adopted for wider cracks or development trend.

Transverse cracks at the bottom of the beam

Transverse shear

Cause analysis: the diaphragm shedding leads to the stress of the beam veneer, under the repeated action of vehicle dynamic load, the shear force produces and leads to cracks.

Disposal suggestion: the transverse crack at the bottom of the beam will affect the safety of the driving. It is suggested that the cracks should be blocked first, then the method of sticking carbon fiber fabric is used to reinforce it, and the observation should be carried out further. When the width of the crack is about 0.5mm, the beam should be replaced.

Lower tension

Cause analysis: the lower reinforcement is tensile and relaxation, and the concrete produces transverse cracks due to tension.

Treatment suggestion: it is suggested that the cracks should be blocked first, and then the method of sticking carbon fiber fabric is used to reinforce it, and the observation should be carried out further. When the width of the crack is about 0.5mm, the beam should be replaced.

Transverse crack of box girder wing plate

Cause analysis: generally caused by shrinkage of concrete. The roof and web concrete of the top plate of the box girder are poured after 7~8 days after pouring. The difference between the roof, the wing plate and the web age is 7~8d, and the shrinkage rate is quite different. So the concrete shrinkage of the roof and especially the long strip of the wing is restrained by the joint of the grid, the floor and the cross beam.

Suggestions for disposal: it is suggested to seal it surface, apply the special epoxy mortar on its surface repeatedly, make mortar infiltrate into cracks, seal the cracks and observe the diseases at the same time. If it has a serious trend, the foundation treatment should be carried out, and the cracks should be grouted.

Longitudinal cracks in the web of box girder

Reason analysis: the longitudinal cracks occur during the operation, which is related to the mass of concrete, such as the excessive tensile force (unreasonable design or construction overstretching), for example, the decrease of concrete bearing capacity caused by the reaction of alkali aggregate.

Disposal suggestion: Because this kind of crack is located in the main part of the steel bundle, it is easy to cause longitudinal steel bundle corrosion, which has a great impact on the structure. It is suggested that the surface of the cement should be sealed and the special epoxy mortar should be applied repeatedly on the surface to make the mortar seep into the crack and seal the crack.

Multi channel cracks in the bottom of cast-in-place slab beam

Cause analysis: The reason is more complex, there are construction reasons, late maintenance reasons, the main reason should be its own stress caused by non-structural cracks. When the structural deformation caused by temperature change and concrete shrinkage is limited, the self stress will be produced inside the structure. When the stress reaches the limit value of the tensile strength of concrete, it will cause concrete cracks.

Disposal method: It is suggested that the surface should be sealed and the special epoxy mortar should be applied repeatedly on the surface to make the resin permeate into the crack and seal the crack.

Cable force relaxation of sling

Cause analysis: cables often suffer damage due to corrosion and vibration, resulting in loose cable tension.

Disposal method: as an important component of tension structure, the damage of cables will bring disastrous consequences to the structure. The cable force of the damaged cable will change, and the change of the cable force will affect the structural internal force distribution and the structure line type, so the cable force can be used as an important index for the assessment of structural health. Therefore, we must accurately understand the state of cable force. It is suggested that special tests should be carried out to fully understand its technical status.

The longitudinal wind and hole of the masonry arch main arch

Main arch ring hole, stone masonry fall block: the abutment empty block used new block filling replacement, replacement should ensure the inlay or stuffing tight, after the replacement should be re - seam treatment. For longitudinal cracks, epoxy resin or cement mortar should be taken in time, and the cracks should be observed and observed. Once the limit (0.5mm) is beyond the limit, the measures should be taken to reinforce the cracks.

Puede encontrar cualquier cosa que necesite, confíe en probar estos productos y encontrará la gran diferencia después de eso.

Tejido de fibra de carbono unidireccional de alta resistencia para refuerzo de compuesto de polímero reforzado con fibra (FRP).

Lámina de fibra de carbono pultruída para reforzamiento de estructuras

Placa / laminado / banda de polímero pretensado reforzado con fibra de carbono (CFRP) para la losa, refuerzo del haz