Anclaje posterior a la instalación y plantación de varillas de r

Adhesivo de anclaje para varillas de refuerzo HM

En este proyecto, el refuerzo es principalmente para el anclaje posterior a la instalación y la plantación de varillas de refuerzo, y el adhesivo de anclaje de varillas de refuerzo HM se utiliza en el producto de varillas de refuerzo, y el siguiente proceso se puede llevar a cabo después de que el pegamento de varillas de refuerzo esté completamente curado para cumplir con los requisitos del diseño.

1. De acuerdo con los requisitos de los planos de diseño (sala de trabajo del distrito A), la columna de la estructura original debe reforzarse con un revestimiento de acero con acero angular de 100 x 6 y una placa de 40 x 4 de espesor con el eje /A-D al eje A-F -0,1 m hasta el primer piso del primer piso del eje al eje A-12.

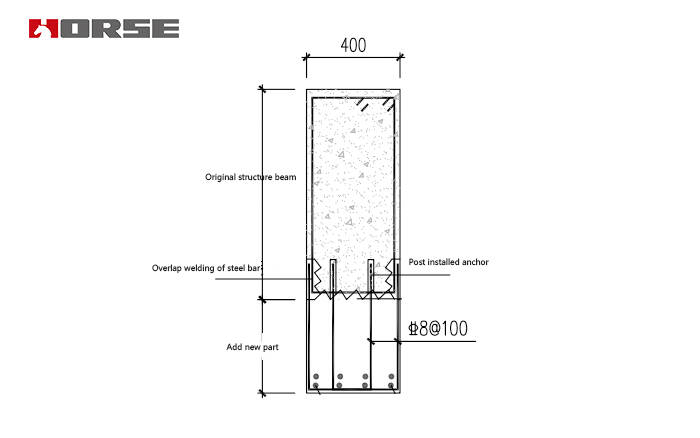

2. De acuerdo con los requisitos de los planos de diseño (sala de trabajo del distrito A), el eje A-10 al eje A-12 / eje A-D al eje A-F para aumentar la sección de la nueva barra reforzada y el estribo en la estructura original.

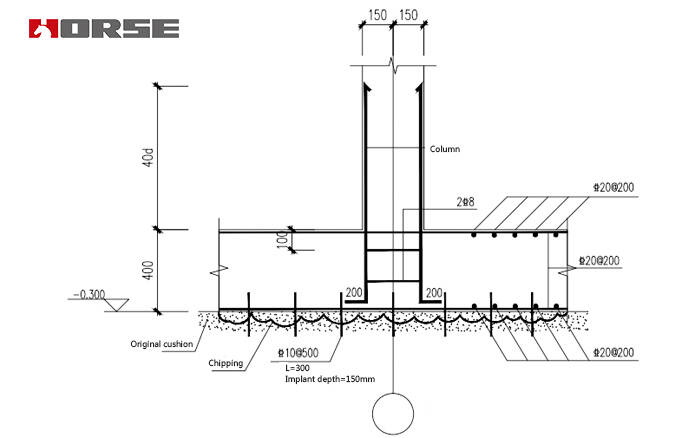

3. De acuerdo con los requisitos de los planos de diseño (diseño de la base entre capas de la sala de distribución de energía del distrito B), se agregan las nuevas losas de válvulas básicas al eje B-6 ~ B-10 / eje B-A a B-B, y los tendones cortos se implantan después de limpiar la superficie original del cincel.

4. De acuerdo con los requisitos de los planos de diseño (diseño de la base entre capas de la sala de distribución de energía del distrito B), la distancia entre la barra de acero HRB400-10 es de 500 mm y la longitud de 300 mm se implanta en los 150 mm después de la limpieza del cabello de la capa de amortiguación de la primera escalera de carrera.

5. De acuerdo con el aviso de cambio de diseño, se deben perforar los muros de los ejes C-3 a C-4, C-9 y C-10 mediante un taladro estático. Tras la perforación, se implanta el nuevo refuerzo HRB400-16 en la estructura original para reforzar el muro.

En este proyecto, el refuerzo es principalmente para el anclaje posterior a la instalación y la plantación de varillas de refuerzo, y el adhesivo de anclaje de varillas de refuerzo HM se utiliza en el producto de varillas de refuerzo, y el siguiente proceso se puede llevar a cabo después de que el pegamento de varillas de refuerzo esté completamente curado para cumplir con los requisitos del diseño.

La columna del marco original está reforzada con un revestimiento de acero. Se utilizan ángulos de acero de 100 x 6 mm de espesor y 40 mm de ancho con una separación de 200 mm mediante adhesivo de placa de acero de perfusión HM. Tras la aceptación, la superficie debe ser anticorrosiva e ignífuga.