Soluciones

La gama de negocios de construcción de caballos se extiende a todo el mundo y sirve a miles de clientes con productos, orientación técnica especializada en construcción, y somos testigos del reinicio de la marca china con ellos.

The main technology is to use epoxy mortar to repair the exposed reinforcement and concrete defects in the beam body. The advanced carbon fiber reinforcement technology is applied to reinforce the above highway bridges so as to improve the bearing capacity and durability of the bridge structure.

Project overview

The former canal and provincial highway have been undertaking heavier transportation tasks. In recent years, the traffic volume is increasing. Higher requirements for the safe operation of the provincial roads are put forward. After years of operation, in the bridge inspection process, found that the Pu Wei highway bridge (part of Pu Wei Longquan port, port, port battle Maqiao bridge) portion of the slab beam fine crack obviously, considering the safety of the bridge structure,district highway department to arrange the cracks of plate beam by carbon fiber reinforcement reinforcement plan. The main technology is to use epoxy mortar to repair the exposed reinforcement and concrete defects in the beam body. The advanced carbon fiber reinforcement technology is applied to reinforce the above highway bridges so as to improve the bearing capacity and durability of the bridge structure.

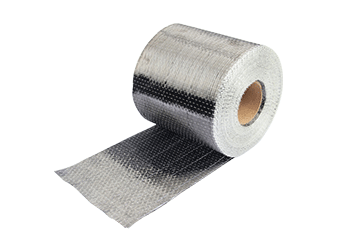

(highway bridge with carbon fiber reinforced polymer CFRP fabric)

Engineering scope

The maintenance and reinforcement project of Longquan port, the main battle of Hong Kong, Hong Kong, bridge 3 bridge maintenance construction, advanced line qiaokong scaffording, then the existence of cracks in the beam reinforced with carbon fiber, so as to improve the bearing capacity and durability of bridge structure.

Construction period

The total schedule of the plan is about 28 days.

Plan start date: the scheduled completion date of 10 06 month 2011: 07 month, 7, 2011

Main workload of unit engineering

Externally bonded carbon fiber reinfroced polymer(cfrp) at the bottom of the beam, combined with 162.00m2

Structural strengthening materials

HM-30 unidirectional carbon fiber fabric

HM-180C3P carbon fiber adhesive

Carbon Fiber fabric and carbon fiber adhesive's datasheet

| Dry Fiber Typical Properties | |

| Standrad Value of Tensile Strength | 4900MPa(7.1×105psi) |

| Tensile Elastic Modulus | 234500MPa(34×105psi) |

| Elongation | 1.7% |

| Laminate Fiber Typical Properties | ||

| Standrad Value of Tensile Strength | 3800MPa(5.51×105psi) | |

| Tensile Elastic Modulus | 234500MPa(34×105psi) | |

| Elongation | 1.7% | |

| With Concrete | Concrete Damaged: ≥2.5MPa | |

| Densiy | 1.8g/cc(0.065lbs.in3) | |

| HM-30 | 0.167mm(0.0065in.) | |

| The properties after carbon fiber adhesive | |||||

| Colloidal performance | Compressive strength(MPa) | ≥70.0 | Working performance | Nonvertical mobility(mm), 30℃ | 2.0 |

| Tensile strength(MPa) | ≥40.0 | Operable time(min), 30℃ | >40 | ||

| Bending Strength(MPa) | ≥50.0 | Applicable Temperature(℃) | 5~40 | ||

| Elastic strength(MPa) | ≥2500 | ||||

| Bonding capacity | Steel-steel tensile shear strength(MPa) | ≥14 | Mixing ratio | A:B=2:1 | |

Pulling bonding strength along with concrete(MPa) | ≥2.5 | Curing time(d),25℃ | 3~7 | ||

| Steel-concrete tensile | C60 concrete damage | ||||

Puede encontrar cualquier cosa que necesite, confíe en probar estos productos y encontrará la gran diferencia después de eso.

Tejido de fibra de carbono unidireccional de alta resistencia para refuerzo de compuesto de polímero reforzado con fibra (FRP).

Impregnación y pasta de componentes reforzados de superficie y productos de fibra.