Soluciones

La gama de negocios de construcción de caballos se extiende a todo el mundo y sirve a miles de clientes con productos, orientación técnica especializada en construcción, y somos testigos del reinicio de la marca china con ellos.

FRP wrap has been widely used to repair and reinforce concrete structures in recent years because of its high strength-weight ratio, corrosion resistance and easy construction.

Introduction

As a new type of material, FRP wrap has been widely used to repair and reinforce concrete structures in recent years because of its high strength-weight ratio, corrosion resistance and easy construction. The common reinforcement method is to use building structural adhesive to paste CFRP wrap on the tensile surface of concrete beams and slabs, or wrap concrete columns to reinforce the structure. However, the fire resistance of CFRP wrap reinforced concrete structures is very poor. The ambient temperature of concrete structures strengthened and repaired with CFRP wrap should not be higher than 60 C for a long time. On the one hand, most of the adhesives used to paste carbon fiber sheets are epoxy. When the temperature exceeds the glass transition temperature (Tg), the adhesives decompose or soften, thus losing the shear force between the fibers and preventing the fibers from buckling. On the other hand, under aerobic conditions, when the temperature is higher than 400 C, CFRP wrap will be oxidized obviously, and the combustion will release toxic smoke. It is found that the CFRP reinforced structure without any fire protection measures can hardly meet the fire resistance requirements. Therefore, taking good protective measures to improve the fire resistance of CFRP wrap reinforced concrete structure has a very significant role. Researchers at home and abroad have done a lot of experimental research and theoretical analysis on the fire protection measures and improvement of fire resistance performance of CFRP reinforced concrete members, and have achieved fruitful research results. Based on the analysis of existing research literature at home and abroad, taking CFRP reinforced concrete structure as the research object, this paper mainly expounds the comparison of fire protection materials used in CFRP wrap reinforced concrete structure at present, systematically summarizes the factors affecting its fire resistance, and points out some problems to be studied.

Comparison of existing fire protection materials

Because CFRP wrap itself does not have sufficient fire resistance, and CFRP wrap is mainly used for reinforcement and repair, it is not used as a fire-proof material, so the code requires that after strengthening the concrete structure with CFRP wrap, the surface of the reinforced and repaired structure should be protected. The fire-resistant materials and their treatment methods should be used to achieve the required fire protection grades of the buildings after reinforcement. When reinforced structures are in other special environments, effective protective materials should be selected according to specific circumstances. At present, the main fire protection materials used in CFRP wrap reinforced concrete structures are: thick fire retardant coating, ultra-thin fire retardant coating, fire prevention board and ordinary cement mortar.

(1) Thick fire-retardant coatings: The mechanism of thick fire-retardant coatings is to prevent and consume fire heat to the surface of the substrate by making use of the good thermal insulation of high-efficiency insulation materials inherent in the coatings and the heat absorption effect of additives, so as to alleviate the critical temperature of the substrate. Thick fire retardant coatings not only have obvious advantages in fire resistance, but also have the characteristics of water-borne, low cost and good weather resistance. A 40 mm thick coated fire retardant coated protective beam was used for fire resistance test. The surface temperature of CFRP was about 225 C after 2 hours of fire, and the fire resistance limit of the specimen was 125 min, which exceeded the fire resistance limit of the first grade required by the Code for Fire Protection in Architectural Design (GB 16-87) for 2.0 H. This shows that the method has better fire prevention effect. Thick coatings are prone to shrinkage and cracking due to the thickness of the coatings, so the thickness of each coatings does not exceed 10 mm, and the coatings need to be fixed with wire mesh and expansion bolts.

(2) Ultra-thin fire retardant coatings: a large number of inert gases are released by thermal decomposition under high temperature of fire, which reduces the concentration of combustible gases and oxygen in the air, and slows down or suppresses the combustion. In addition, when the coating is fired, it expands and foams, forming a light porous carbonized foam layer, which can effectively prevent heat transfer to the substrate. The reinforced beams with ultra-thin fire retardant coatings for fire protection were experimentally found to have wider cracks in the coating at the beginning, and then with the increase of foaming thickness, the wider cracks between the coatings were filled slowly. Comparatively speaking, the fire resistance of ultra-thin fireproof coating is inferior to that of thick fireproof coating. In order to enhance the adhesion between coatings and CFRP wrap, in addition to the wire mesh between coatings and CFRP wrap, a small amount of quartz sand should be sprayed outside.

(3) Fire-proof board: generally, it is made of inorganic material as the base material, and adding various modified materials after a certain process. This kind of board can maintain a certain strength in fire, and has good dimensional stability and fire insulation performance. The 40 mm thick calcium silicate fire-proof board was used as the protective layer under IS0834 standard heating curve for 122 minutes, and the final deflection was 143.6 mm. According to the stipulation of Fire Resistant Test Method for Building Components, the criterion for determining the fire resistance limit of specimens is that the specimens collapse or the maximum deflection of specimens exceeds L/20 during the test, in which L is the fire span of the specimens, unit mm. The actual fire span of the beam is 4m, and the maximum deflection limit is 200mm. Therefore, the fire protection board can still achieve better fire protection effect.

(4) cement mortar: sprayed or manually painted, cement mortar will be applied to the surface of reinforcement components. Cement mortar is not a fire-proof material. It is suggested that ordinary cement mortar can also be used as a fire-proof protection measure for strengthening concrete beams under the condition of low fire-proof limit. In order to avoid premature shedding of CFRP wrap, U-shaped steel wire mesh should be set between cement mortar and CFRP wrap, and expansion screws should be set at the top of the beam on both sides to reinforce the steel wire mesh.

Main factors affecting fire resistance

According to the existing literature, the factors affecting the fire resistance of CFRP wrap reinforced concrete beams are: the thickness of concrete cover, load ratio, CFRP wrap reinforcement, coating thickness, Span-to-height ratio, thermal performance of fire-resistant materials.

Puede encontrar cualquier cosa que necesite, confíe en probar estos productos y encontrará la gran diferencia después de eso.

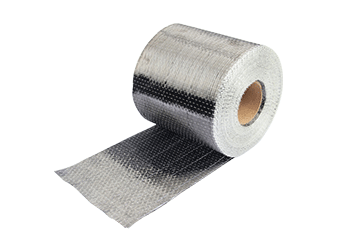

Tejido de fibra de carbono unidireccional de alta resistencia para refuerzo de compuesto de polímero reforzado con fibra (FRP).

Adhesivo de nivelación de fibra de carbono de buena tixotropía para la reparación de superficies de concreto

Impregnación y pasta de componentes reforzados de superficie y productos de fibra.