Soluciones

La gama de negocios de construcción de caballos se extiende a todo el mundo y sirve a miles de clientes con productos, orientación técnica especializada en construcción, y somos testigos del reinicio de la marca china con ellos.

CFRP fabric reinforcement of reinforced concrete columns can change the axial stress state of concrete into three-dimensional stress state, and improve the bearing capacity and deformation capacity of confined concrete

Carbon fiber fabric is the most widely used and popular structural strengthening materials in the civil engineering field. This reinforcement technology rose in the 1980s and developed rapidly in China in the late 1990s. Many research institutes and universities at home and abroad have done a lot of research on carbon fiber fabric reinforcement of concrete members. With the deepening of experimental research, the application scope of the reinforcement technology is expanding and the application technology is improving.

The experimental study on carbon fiber fabric strengthening RC columns is relatively few, but the experimental results show that CFRP fabric strengthening RC columns has the characteristics of simple construction, strong corrosion resistance, good restraint effect, and basically no maintenance. The following reinforcement technology is briefly introduced.

1. Mechanism analysis of reinforced concrete columns strengthened with carbon fiber fabric

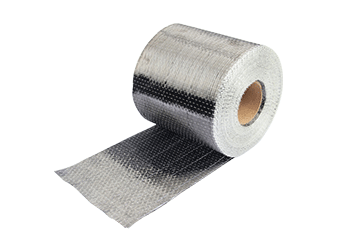

1.1. Carbon fiber reinforced polymer (CFRP) fabric

Carbon fiber fabric CFRP is generally a continuous fiber with a diameter of 5-20 micron. The base material is composed of resin and curing agent. The carbon fiber is soaked with resin (internal reinforcer). When the resin is cured, a carbon fiber reinforced plastic (CFRP) is formed. Its characteristics: low density, for ordinary steel 1/6. The tensile strength is about 4~6 times that of the ordinary steel bar. Corrosion resistance is good, strength is not affected by acid and alkali corrosive medium. Non magnetism does not affect the propagation of electromagnetic signals. Fatigue resistance is excellent and fatigue life is generally higher than steel. The coefficient of temperature variation is equivalent to that of concrete. The elastic modulus is similar to that of steel. Limit elongation 1%.

1.2, the principle of carbon fiber fabric reinforced concrete columns.

When reinforced concrete columns are subjected to axial compression, members are caused by lateral expansion with very small limit value. For example, transverse constraints can be created around the members to prevent such lateral expansion of compressive members, so as to improve the compressive capacity and deformation capacity of members.

CFRP reinforcement of reinforced concrete columns is to produce restraint between the column concrete and CFRP reinforcement zone (the interaction between them is called interface restraint stress) by the transverse interface restraint stress, plastic zone of the core concrete in the three-dimensional stress state. The ultimate compressive strain and load-bearing capacity of reinforced concrete columns are higher than those under unidirectional loading, and the ductility deformation and energy dissipation capacity of reinforced concrete columns are larger when the flexural bearing capacity of columns is not significantly reduced without considering the effect of instability.

1.3. The stress distribution of reinforced concrete columns under the action of wrapping carbon fiber fabric.

1.3.1 The ultimate ultimate axial compressive strength of rectangular columns enclosed by CFRP fabric is much lower than that of circular columns due to the axial tensile stress of CFRP fabric formed by the transverse restraint of CFRP fabric on reinforced concrete columns, but the bending resistance of CFRP fabric is very weak (generally not considered). The lateral restraint at the center of the rectangular column edge is weak and the lateral stress concentration restraint at the corner is large. The lateral restraint stress of CFRP fabric on the reinforced concrete column can increase rapidly only when the lateral plastic deformation occurs at the column edge.

1.3. In the first stage, the axial compressive stress of concrete is small, the transverse deformation is small, and the CFRP force is small. In the second stage, with the increase of load, the deformation of column concrete increases, the circumferential stress of carbon fiber fabric increases significantly, and the circumferential restraint force increases rapidly until CFRP fabric reaches its ultimate tensile strain.

Conclusion

1) CFRP fabric reinforcement of reinforced concrete columns can change the axial stress state of concrete into three-dimensional stress state, and improve the bearing capacity and deformation capacity of confined concrete, especially for reinforced concrete columns whose axial compression ratio can not meet the requirements of seismic design code.

2) To improve the bearing capacity and ductility of the plastic hinge area, the plastic hinge area will appear at the upper and lower ends of the reinforced concrete columns under the repeated earthquake loads, and the bearing capacity and ductility will decrease rapidly. The ultimate strength and deformation capacity of the core concrete in the plastic hinge area will be greatly improved after winding and strengthening with CFRP fabric.

3) The construction technology is low in content, simple in process, good in restraint effect and strong in corrosion resistance, and only needs protection without maintenance.

4) Carbon fiber fabric reinforcement technology is not omnipotent, has its shortcomings: poor high-temperature resistance of organic glue, high-temperature environment and fire prevention grade requirements can not be used in buildings; irregular or large-section rectangular columns should be conditionally used.

Puede encontrar cualquier cosa que necesite, confíe en probar estos productos y encontrará la gran diferencia después de eso.

Tejido de fibra de carbono unidireccional de alta resistencia para refuerzo de compuesto de polímero reforzado con fibra (FRP).

Imprimación de fibra de carbono de baja penetración y alta penetración para superficies de concreto reforzado

Impregnación y pasta de componentes reforzados de superficie y productos de fibra.