Soluciones

La gama de negocios de construcción de caballos se extiende a todo el mundo y sirve a miles de clientes con productos, orientación técnica especializada en construcción, y somos testigos del reinicio de la marca china con ellos.

In residential building project, before the construction of cushion layer and surface layer, cracks less than 0.3 mm were found in cast-in-situ concrete slab, and leakage was found after water injection. After core drilling, it was found that the cracks were caused by concrete strength and slab thickness not meeting the design requirements.

In residential building project, before the construction of cushion layer and surface layer, cracks less than 0.3 mm were found in cast-in-situ concrete slab, and leakage was found after water injection. After core drilling, it was found that the cracks were caused by concrete strength and slab thickness not meeting the design requirements.

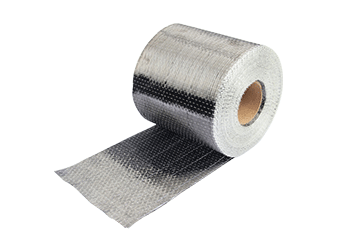

Sticking carbon fiber fabric(CFRP)

The principle of bonding CFRP is the same as that of bonding steel plate. CFRP is used instead of steel plate to bond CFRP to the surface of concrete members, so that CFRP and concrete members work together to improve the bearing capacity of the members. Carbon fiber has the advantages of high strength, corrosion resistance, easy construction, and basically unchanged size after reinforcement, so it is widely used in the reinforcement of various concrete components.

Crack injection

1.crack inspection

2.crack treatments

3.embed pouring glue nozzle

4.seal crack

5.sealing check

6.prepare pouring crack adhesive

7.pour glue

8.conservation

9.examination and test

Treatment of floor thickness

Post installed anchoring

1.Drill hole to the diameter and depth required. The diameter must be in accordance with anchor size.

2.The drill hole must be cleaned with air blower, starting from the bottom of the hole.The drill hole mustbe thoroughly cleaned with steel brush. After brush, to use air blower to clean the drill hole again.

3.Inject resin anchor resin into the hole, starting from the bottom, while slowly drawing back the static mixer. In any case avoid entrapping air. For deep holes extension tubing can be used.

4.Insert the anchor with a rotary motion into the filled drill hole. Some adhesive must come out of the hole.

5.During the resin hardening time the anchor must not be moved or loaded.

Test of floor deflection and crack width

1)Sampling of test components. The cast-in-place floor slab has been strengthened by pasting carbon fiber, planting negative moment reinforcing bar and laminating floor. Therefore, random sampling is carried out for static load test.

2) test load. The test only tests the deflection and crack width of the floor. According to the GB 5015292 concrete structure test method standard, the test load is determined according to the normal service limit state load.

The maximum loading value of this test is the floor uniform live load and the brick floor load, the standard value of the floor uniform live load is 2.0 kN/m 2, the brick floor load is 0.7 kN/m 2, the total maximum loading value is 2.7 kN/m 2.

3) measuring instruments and loading equipment. The measuring instrument adopts 10 mm percentile and 50 mm percentile meter, weighing apparatus 1, steel ruler and 40 times scale microscope, and 5 400 clay solid bricks. Weighing 100 bricks on site, the average weight of each brick is 0.0225 kN, and the total weight is 121.5 kN.

4) loading and unloading tests. The test was carried out by six stages loading method. Loading at each stage, the load duration is 10 min, the deformation of each part of the component is measured and the first load is added. All test load values are added, and the load duration is not less than 30 min. In the field test, in order to test the deformation characteristics of the plate, the duration of the maximum test load can be extended to 60 minutes or even more than 12 hours.

The unloading classification is determined according to the deformation of the plate. Three times of unloading, two times of unloading, one time of unloading. The duration of each unloading is 10 minutes. After the unloading of all loads, the duration of deformation recovery is not less than 45 min.

5) deformation and fracture measurement.

A. Deflection measurement points are arranged along the maximum deflection of the two span directions of the floor, and bearing deformation measurement points are arranged at the midpoint of each side of the floor. For a plate of general size, five measuring points can be arranged; for a plate with a span of not less than 6 m, additional measuring points are set at the four-point position in the long span direction.

B. installation of measuring instruments, erection of supports on the floor of the floor, and support shall remain independent. The dial gauge for measuring deformation is installed on the bracket and numbered separately. Do not move again after the instrument is installed.

C. Deformation measurement, before loading, read the initial reading of each dial meter; after loading, after the end of the duration of each stage load, measure the amount of deformation of each part of the component. After each stage of unloading, the remaining deformation of each part of the component is measured.

D. Crack observation, before each loading test, observe whether there are cracks at the bottom of the board and record in detail; during the loading process, pay close attention to the deformation of the floor, carefully observe whether there are cracks at the bottom of the board or the development of cracks, and do a good job of recording. The fracture width was observed by 40 times calibration microscope.

Test result

Short term static load test is adopted. According to the mid-span deformation of the slab under test load, the measured mid-span and short-span deflection after correction, and the long-term deflection calculation considering the long-term effect of load. Combining with the limit requirement of normal service limit state in the Code for Design of Concrete Structures, it is determined whether the floor can meet the limit requirement of deformation and crack width under normal service limit state.

Puede encontrar cualquier cosa que necesite, confíe en probar estos productos y encontrará la gran diferencia después de eso.

Tejido de fibra de carbono unidireccional de alta resistencia para refuerzo de compuesto de polímero reforzado con fibra (FRP).

Resina de anclaje epoxi, paquete de cartucho doble. Se inyecta en los orificios con la pistola dispensadora para plantar barras.

Adhesivo de inyección de grietas epóxicas de muy alta penetración y baja viscosidad para reparar grietas de concreto