Soluciones

La gama de negocios de construcción de caballos se extiende a todo el mundo y sirve a miles de clientes con productos, orientación técnica especializada en construcción, y somos testigos del reinicio de la marca china con ellos.

Evenly spread the well prepared impregnating adhesive on the bonding part. The carbon fiber fabric should be gently pressed and pasted in the position to be pasted according to the direction, position and order of the design.

The configuration of the impregnating adhesive should be allocated according to the technological conditions of the manufacturer's instructions. The mixing should be fully stirred with a low speed mixer. The mixing liquid should be uniform and no bubbles. Dust control measures should be adopted to prevent water, oil and dust from mixing.

Evenly spread the well prepared impregnating adhesive on the bonding part. The carbon fiber fabric should be gently pressed and pasted in the position to be pasted according to the direction, position and order of the design. Compared with the position of the design requirement, the core line deviation should not be greater than 10mm. A special roller is used to roll the fibers in multiple directions to completely squeeze out the bubbles, so that the impregnating glue can be thoroughly infiltrated into the carbon fiber cloth. Be careful not to damage the CFRP when rolling. After the defoaming operation, confirm that the CFRP has no wrinkle and no skew. The above steps should be repeated when multi layer stickup, and when the impregnated adhesive on the surface of the carbon fiber cloth is dry, it should be immediately put into the next layer, and the coating should be smeared evenly on the surface of the last 1 layers of carbon fiber cloth.

If the length of CFRP is not enough to overlap, the length of the lap should not be less than 200mm, and the lap length should not be less than 300mm if the number of sticker layers exceeds 3 layers; the lap length for each side of the horizontal line is 100mm. When the multi-layer carbon fiber cloth is strengthened, the overlap position of the carbon fiber cloth between each layer or each layer should be stagger. Stick to 2 or more layers, and stick to it continuously. Otherwise, the carbon fiber cloth should be cleaned before starting to paste.

Puede encontrar cualquier cosa que necesite, confíe en probar estos productos y encontrará la gran diferencia después de eso.

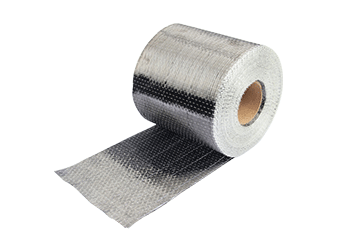

Tejido de fibra de carbono unidireccional de alta resistencia para refuerzo de compuesto de polímero reforzado con fibra (FRP).

Adhesivo de nivelación de fibra de carbono de buena tixotropía para la reparación de superficies de concreto

Impregnación y pasta de componentes reforzados de superficie y productos de fibra.