Soluciones

La gama de negocios de construcción de caballos se extiende a todo el mundo y sirve a miles de clientes con productos, orientación técnica especializada en construcción, y somos testigos del reinicio de la marca china con ellos.

Sticking FRP in the tensile area of concrete structure can effectively improve its bearing capacity and restrain crack propagation. The damage characteristics of the reinforced concrete structure after the FRP reinforcement are different from that of the ordinary concrete structure and the reinforced concrete structure, and the calculation method of its bearing capacity is different.

Sticking FRP in the tensile area of concrete structure can effectively improve its bearing capacity and restrain crack propagation. The damage characteristics of the reinforced concrete structure after the FRP reinforcement are different from that of the ordinary concrete structure and the reinforced concrete structure, and the calculation method of its bearing capacity is different.

FRP can effectively improve the shear ability of the shear zone on the concrete beam. There are 3 methods commonly used in the project, such as flank paste, U type paste and parcel paste, and the best effect is parcels and stickup. The main parameters affecting the shear strength of FRP include the stirrup ratio of the beam, the strength of the concrete, the ratio of FRP, the shear span ratio of the beam, the bonding mode of FRP and the anchorage performance, the properties of the FRP and the material properties of the adhesive itself.

By outsourcing FRP to constrain the plastic hinge area to improve the ultimate compressive strain of the concrete, the ductility of the component can be improved and the seismic strengthening of the structure will be beneficial.

The fatigue of FRP sheets is divided into 2 types: bending fatigue and shear fatigue. According to the load form, fatigue can be divided into constant amplitude load and variable amplitude load. In addition to the fatigue resistance of the original concrete structure, the fatigue strength of the FRP sheet reinforced member is related to the fatigue fracture ability of the reinforced part of the FRP and the anti fatigue failure ability of the FRP sheet and the concrete interface.

For the flexural members with excessive deflection or cracking serious concrete beams and plates, the simple FRP patch reinforcement method is difficult to effectively enhance its stiffness, and the function of the material can not be fully utilized. The prestressed FRP reinforcement technology can balance the partial load of the beam, effectively reduce the deflection and deformation of the reinforced beam, delay Liang Kailie, reduce the crack width, reduce the possibility of early peeling damage, and improve the bearing capacity of the beam.

Under the bad environment, the performance of CFRP is better than that of GFRP. Under dry and wet effect, the strength and ductility of CFRP restraint specimens are not reduced, and the stiffness is improved, while the strength and ductility of the GFRP constrained specimens are both reduced and the stiffness is not affected. Under the effect of freeze-thaw cycle, the strength and ductility of the CFRP and GFRP restrained specimens were significantly reduced, and the stiffness was not affected. Compared with the room temperature and the dry and wet cycle, the failure mode of the frozen thawing test specimen was more disastrous. After seawater corrosion, the bearing capacity of reinforced concrete beams and columns strengthened by ordinary reinforced concrete beams, columns and CFRP has been reduced, but the stiffness of CFRP reinforced concrete beams has hardly been affected by any effect. Freeze-thaw cycles have adverse effects on the mechanical properties of FRP strengthened concrete beams.

Puede encontrar cualquier cosa que necesite, confíe en probar estos productos y encontrará la gran diferencia después de eso.

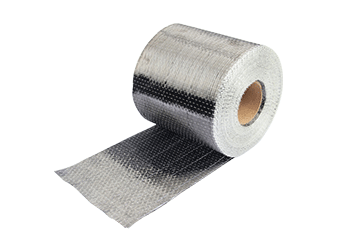

Tejido de fibra de carbono unidireccional de alta resistencia para refuerzo de compuesto de polímero reforzado con fibra (FRP).

Adhesivo de nivelación de fibra de carbono de buena tixotropía para la reparación de superficies de concreto

Impregnación y pasta de componentes reforzados de superficie y productos de fibra.