Soluciones

La gama de negocios de construcción de caballos se extiende a todo el mundo y sirve a miles de clientes con productos, orientación técnica especializada en construcción, y somos testigos del reinicio de la marca china con ellos.

How to control cracks in shear walls? Epoxy injection concrete crack repair shear wall. FRP composite strengthening shear wall.

The shear wall is a kind of aseismic and wind resistant wall with very high hardness. But in the course of use, there will be different degrees of cracking, today we summarized the control measures of shear wall cracks, let's see.

1.1 Classification of shear walls

Before choosing the shear wall reinforcement scheme, we must know the force condition of the shear wall. Generally, shear walls are divided into the following types according to the size, number and arrangement of holes in shear walls.

1.1.1 Whole wall

When the total area of the entrance of doors and windows is less than 15% of the side area of the shear wall, and the net distance between the entrance and the hole to the wall is larger than the length of the entrance, the whole wall is formed.

1.1.2 Small opening integral wall

The opening size of doors and windows is larger than that of the integral wall. At this time, local bending moment has appeared in the wall legs. This kind of wall is called small opening integral wall.

1.1.3 Joint wall

There are one or more rows of openings in the shear wall, and the size of the openings is relatively large. At this time, the shear wall is equivalent to a series of wall legs connected by the beams between the openings, so it is called the connecting wall.

1.1.4 Frame supported shear wall

When the bottom needs large space, the frame supported shear wall is formed by supporting the upper shear wall with frame structure. In the seismic area, pure frame supported shear wall structure is not permitted.

1.1.5 Wall frame

If the opening of the shear wall is bigger, the stiffness of the shear wall is weaker and the stiffness of the connecting beam is stronger, the shear wall is close to the frame. Because the thickness of the shear wall is smaller than the width of the beam column of the frame structure, it is called the wall type frame.

1.1.6 Shear walls with irregular openings

Sometimes due to the requirements of building use, it is necessary to open a larger hole in the shear wall, and the arrangement of the hole is irregular, that is, for this type.

2.1 Epoxy injection concrete crack repair

Epoxy injection concrete crack repair key features: strong penetration, low viscosity, aging, water resistance and acid and alkaline. It does not contain volatile solvents and does not shrink when hardened. After curing, it has excellent toughness and impact resistance to seal the cracks, so that the steel bar and air in the component are isolated, to avoid premature oxidation and corrosion of the steel bar. Connecting the concrete on both sides of the crack makes the concrete on both sides of the crack work together, and achieves the effect of waterproof and leak plugging.

Epoxy injection concrete crack repair application: concrete bridges, houses, water conservancy, pavement and other projects, as well as in the concrete honeycomb, loosening and other defects of reinforcement glue repair, FRP anti-corrosion, structural surface coating anti-corrosion, construction. It is suitable for pouring and bonding the cracks in concrete and brick-concrete components to achieve the purpose of repairing and strengthening the cracks.

Matters needing attention in construction of epoxy injection concrete crack repair

(1) use high quality sealant and potting compound.

(2) crack surface treatment should be thorough to ensure the tightness of crack closure.

(3) Grouting nozzles must be arranged at the forks of cracks, and the number of grouting nozzles for each crack shall not be less than two;

(4) In the process of fissure grouting, vertical fissures should be grouted from bottom to top, and horizontal fissures should be grouted from low end to high end.

(5) When injecting glue from the bottom to the top, pull out the adjacent injection nozzles above, and when the glue comes out, plug into the injection nozzle, keep the pressure of the injection machine above 0.4 MPa, so that the glue is fully filled with cracks.

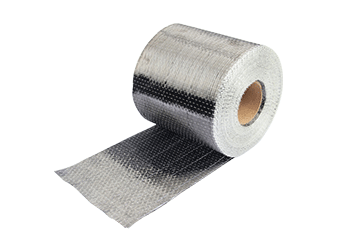

2.2 FRP composite strengthening

FRP composite strengthening key feature: save space, construction is simple, does not need site fixed facilities, construction quality is easy to ensure, basically does not increase the size and weight of the structure, corrosion resistance, good durability and so on.

FRP composite strengthening application: wide range of use, concrete components, steel structure, wood structure can be reinforced.

Puede encontrar cualquier cosa que necesite, confíe en probar estos productos y encontrará la gran diferencia después de eso.

Tejido de fibra de carbono unidireccional de alta resistencia para refuerzo de compuesto de polímero reforzado con fibra (FRP).

Adhesivo reparador de grietas de alta resistencia para grietas de hormigón.

Adhesivo de inyección de grietas epóxicas de muy alta penetración y baja viscosidad para reparar grietas de concreto