Soluciones

La gama de negocios de construcción de caballos se extiende a todo el mundo y sirve a miles de clientes con productos, orientación técnica especializada en construcción, y somos testigos del reinicio de la marca china con ellos.

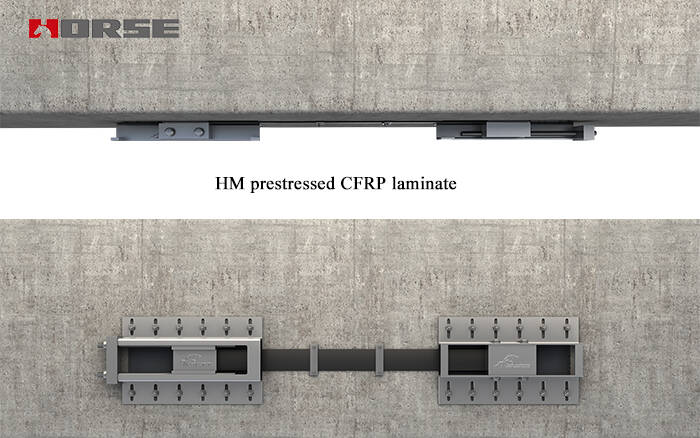

The prestressed CFRP laminate reinforcement system consists of three parts: anchorage, carbon fiber laminate and carbon fiber laminate adhesive.

The prestressed CFRP laminate reinforcement system consists of three parts: anchorage, carbon fiber laminate and carbon fiber laminate adhesive.

Anchorage

The anchorage realizes the stretching and fixing of the carbon fiber laminate. The carbon plate adhesive makes the carbon fiber laminate and the reinforced component form a common force.

In the reinforcement system, anchorage is the key.

Carbon fiber laminate

Carbon fiber laminate is the highest tensile strength man-made fiber. Its elastic modulus is 150-170GPa, tensile strength up to 2800 MPa, and the elastic modulus of steel is generally about 200 GPa, tensile strength is only about 300 MPa.

Carbon fiber laminate has some other excellent characteristics: it has light weight, no additional increase in the weight of the reinforced structure, stable properties, weak acid, weak alkali, freeze-thaw cycle, long-term sunshine and other environmental effects on its small.

Carbon fiber laminate adhesive

Carbon fiber laminate adhesive has strong bonding force, long application period, fast strength growth, and is not affected by environmental vibration. It has super fatigue resistance and no shrinkage after curing.

Construction method of prestressed FRP laminate

1. Construction preparation:

(1) erection of construction stents, procurement of main materials and fabrication of anchorage steel members.

(2) Setting out the surface of the reinforced beam according to the design drawings to determine the positions of the carbon fiber board and the anchorage at both ends.

2. Concrete chipping and surface treatment

(1) According to the construction lofting to determine the location of fixed anchorage and tension end anchorage, chisel out the surface of the beam concrete, its depth is 1/2 anchorage thickness, to ensure that the carbon fiber board adhered to all the beam closely combined.

(2) The surface of concrete beams is ground by angle grinder at the position of carbon fiber board, and then wiped with dry cloth to ensure smooth and dust-free adhesive surface.

3. Bolt construction

Planting high-strength screw according to the design drawings at the positions where the tensile end and the fixed end members of the CFRP are installed

4. Manufacture of fixed end anchorage and tension end anchorage

5. Installation and anchorage of fixed end anchorage and tension end anchorage

6. Carbon fiber board adhesive surface is scrubbed with acetone before pasting, then special adhesive is applied on the contact surface between carbon fiber board and beam bottom, and adhesive is applied on the contact surface between anchorage plate and beam bottom.

7. Install the jack, stretch the CFRP and observe the deflection of the beam.

8. Protect

Puede encontrar cualquier cosa que necesite, confíe en probar estos productos y encontrará la gran diferencia después de eso.

Placa / laminado / banda de polímero pretensado reforzado con fibra de carbono (CFRP) para la losa, refuerzo del haz

Es un producto utilizado para la unión de placas de fibra de carbono en el refuerzo.