Reparación de grietas en hormigón

Utilizando tejido de fibra de carbono e inyección de grietas de epoxi

Para garantizar la seguridad estructural, a través del análisis y comparación de las unidades de construcción, supervisión, diseño y construcción, finalmente se utiliza el método de refuerzo de CFRP para reforzar la viga del marco.

El tejido de fibra de carbono (CFRP) es una nueva tecnología de refuerzo en los últimos diez años. Tiene las características de alta resistencia a la tracción, alto módulo de elasticidad, peso ligero, espesor fino, buena resistencia a la corrosión y fácil de usar.

La tecnología de refuerzo de fibra de carbono es el uso de materiales de resina para unir la fibra de carbono a la superficie de las estructuras o componentes, de modo que la fibra de carbono y el hormigón formen un todo compuesto,

a través de su cooperación con la estructura o los componentes, mejore la capacidad de soporte de flexión y cizallamiento de los componentes estructurales. Con el fin de lograr el propósito de fortalecer y reforzar los componentes estructurales y mejorar el rendimiento mecánico.

La tecnología de refuerzo tiene las características de construcción conveniente, uso amplio, sin cambios en la forma y el peso de la estructura, y tiene un gran valor de investigación y divulgación y potencial de mercado.

1 Descripción general del proyecto

Durante la construcción de un edificio de dormitorios, se encontró una ligera grieta pasante en la parte inferior y lateral de una viga del marco con una luz de 6 m. El ancho de la grieta era de aproximadamente 0,2 mm. Para garantizar la seguridad estructural,

mediante el análisis y la comparación de las unidades de construcción, supervisión, diseño y construcción, finalmente se utiliza el método de refuerzo de CFRP para reforzar la viga del marco.

2 Esquema de refuerzo

Antes de la construcción, se retira el material apilado en la parte de la viga del marco para minimizar la carga que actúa sobre la viga del marco durante la construcción de refuerzo, luego se tratan las grietas y finalmente se realiza el refuerzo de fibra de carbono.

Tratamiento de grietas: ancho de grieta menor a 0,2 mm, con sellado de superficie con cepillo de resina epoxi; grietas mayores a 0,2 mm con reparación de inyección de grietas. Refuerzo de fibra de carbono: En primer lugar,

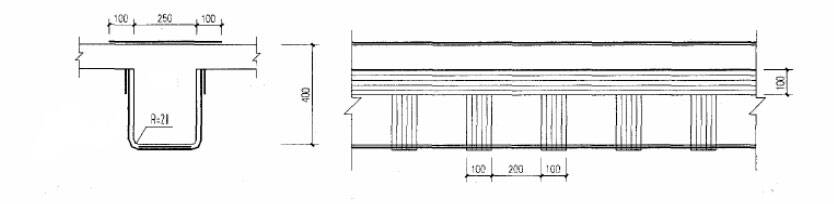

se pega una tira ancha de tela de fibra de carbono con el mismo ancho en la parte inferior de la viga, y luego se pega un aro de "U" de tela de fibra de carbono de 100 mm de ancho con una distancia de 200 mm.

Se pegó una lámina de CFRP de 100 mm de ancho a ambos lados de la viga para reforzar el aro en forma de U. Finalmente, se pegó una lámina de CFRP sobre la superficie de la viga con un ancho de 250+2*100=450 mm, como se muestra en la figura 1.

3 Inyección de resina epoxi para la reparación de grietas

En este proyecto, se adopta la tecnología de construcción de juntas de baja presión automáticas con resina epoxi para reparar y reforzar las microgrietas de la viga del marco.

El proceso utiliza el principio poroso del hormigón y la presión producida por la contracción de la película de caucho elástico sobre la base de inyección de caucho para presionar la resina epoxi con alta fluidez en la grieta y penetrar en la profundidad de la grieta,

con el fin de recuperar el hormigón.

4 Refuerzo de fibra de carbono

Pasos de construcción: tratamiento de la superficie, cepillado del pegamento de imprimación, reparación, nivelación, pegado de la tela de fibra de carbono, curado y prueba.

4.1 Tratamiento de la superficie

(1) Pulir la parte inferior y ambos lados de toda la viga del marco con una máquina de muela abrasiva, eliminando la suciedad, la lechada flotante y la estructura suelta de la capa de superficie de hormigón,

revelando la estructura compacta y alisando la superficie.

(2) Pulir las esquinas de los componentes en arcos circulares con un radio de arco de no menos de 20 mm.

(3) Limpiar el polvo y los elementos diversos de la superficie con un soplador y lavarlos con agua y alcohol. El siguiente procedimiento de trabajo se puede llevar a cabo solo después de que la superficie de hormigón esté completamente seca.

4.2 Aplicación de la imprimación

(1) El agente principal y el agente de curado de la resina subyacente se pesan con precisión de acuerdo con la proporción prescrita y luego se colocan en el recipiente especial. El agente principal se pesa primero, luego se agrega el acelerador de curado,

se agita uniformemente y luego se agrega el agente de curado después de 1-3 minutos y se agita uniformemente con el agitador; la cantidad de mezcla debe usarse dentro del tiempo de servicio (aproximadamente 30-40 minutos).

(2) La resina inferior se recubre uniformemente sobre la superficie del concreto con un cepillo de rodillo especial, y la construcción del siguiente proceso se puede llevar a cabo solo después de que la superficie de la resina se toque y se seque (la superficie de la resina se solidifica y endurece).

(3) La resina subyacente se refiere al secado o curado por contacto, la superficie de la parte convexa (similar a la gota de rocío) para usar un paño abrasivo o una máquina pulidora niveladora.

4.3 Nivelación de parches

(1) Preparación de masilla epoxi: agente principal de masilla, acelerador de curado, agente de curado de acuerdo con la proporción prescrita, pesados con precisión en el recipiente, agregando secuencia con los requisitos de construcción de resina inferior,

revolviendo uniformemente con un mezclador; La cantidad de mezcla debe agotarse dentro del tiempo de uso (aproximadamente 40-50 minutos).

(2) La superficie cóncava del componente se llena con masilla epoxi y la superficie es lisa y lisa sin ninguna esquina. La esquina también debe repararse hasta formar un arco circular liso con un radio de no menos de 20 mm.

(3) La superficie de la masilla se raya y se raya, y se utiliza papel de lija para lijar y nivelar.

4.4 Pasta de tela de fibra de carbono

(1) La tela de fibra de carbono debe cortarse de acuerdo con la dimensión del diseño de refuerzo. La tela de fibra de carbono debe cortarse en la misma dirección que la parte de unión. Se debe prohibir el corte oblicuo de la tela de fibra de carbono y se debe evitar el trefilado.

La tela de fibra de carbono después del corte debe enrollarse para evitar arrugas y dobleces.

(2) El agente principal y el agente de curado de la resina impregnada se pesan con precisión de acuerdo con la proporción prescrita y se agitan uniformemente en un mezclador para cargar en un recipiente.

Se debe utilizar una cantidad armónica dentro del tiempo disponible (aproximadamente 50 ~ 60 minutos).

(3) Vuelva a limpiar la superficie de hormigón antes de pegar la fibra de carbono. Después de confirmar que no hay polvo en la superficie, aplique resina epoxi de manera uniforme en el lugar donde se va a pegar. Al cepillar la resina, se deben lograr los requisitos de "estable, preciso y uniforme",

es decir: estable, fuerza de cepillado moderada, en la medida de lo posible no fluir ni caer; preciso, preciso en el lugar de cepillado, cepillado y sin línea de control; uniforme, espesor uniforme dentro del alcance del cepillado.

(4) Pegado de tela de fibra de carbono, lo mismo que "estable, preciso y uniforme", para lograr una resistencia moderada, de modo que la tela de fibra de carbono no se arrugue, no se doble, se extienda suavemente. Al enrollar la tela de fibra de carbono,

se debe enrollar muchas veces de un extremo al otro con un tambor especial para extruir burbujas. No es adecuado enrollar y frotar repetidamente en una parte. Durante el enrollado, la resina impregnada debe permear la tela de fibra de carbono lo suficiente para lograr la saturación.

Cuando la lámina de fibra de carbono necesita ser lapeada, la longitud de lapeado debe ser mayor a 100 mm, y se debe garantizar la calidad de infiltración de resina de la parte lapeada.

(5) Al pegar sobre la superficie de la tela de fibra de carbono, la siguiente capa debe pegarse sobre la superficie de la tela de fibra de carbono. Si son más de 40 minutos, se debe esperar 12 horas, luego se debe cepillar el aglutinante para pegar la siguiente capa.

4.5 La tela de fibra de carbono debe mantenerse después del curado, se debe garantizar estrictamente que el período de curado (especialmente el período de curado inicial) no se vea afectado ni colisione, el período de curado es de aproximadamente 1 semana.

4.6 Los criterios de inspección y aceptación para la calidad de la construcción son los siguientes:

(1) En comparación con los requisitos de diseño, la desviación permitida de la línea central es menor a 10 mm.

(2) La cantidad de pasta de fibra de carbono debe ser grande.

(3) Calidad de adherencia: A. cuando el área de un solo tambor vacío es menor a 1000 mm2, se repara rellenando con pegamento; cuando el área de un solo tambor vacío es mayor a 1000 mm2, se repara cortando; B.